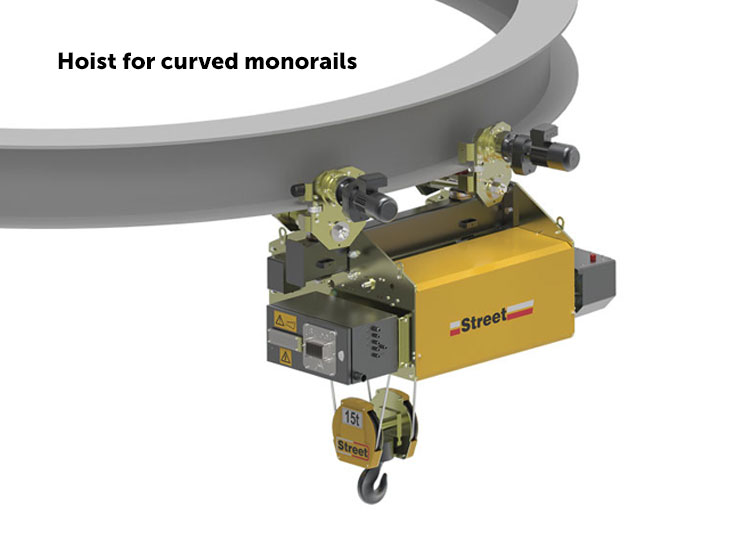

Some typical features which may be incorporated into special hoisting equipment are as follows:

- Extra fast speed/arduous duty combinations.

- Advanced integrated control systems and safety rated control to EN13849 Category 3 PLd.

- Extra large lifting heights.

- Multiple synchronised hoists or multi point lifting from a single hoist.

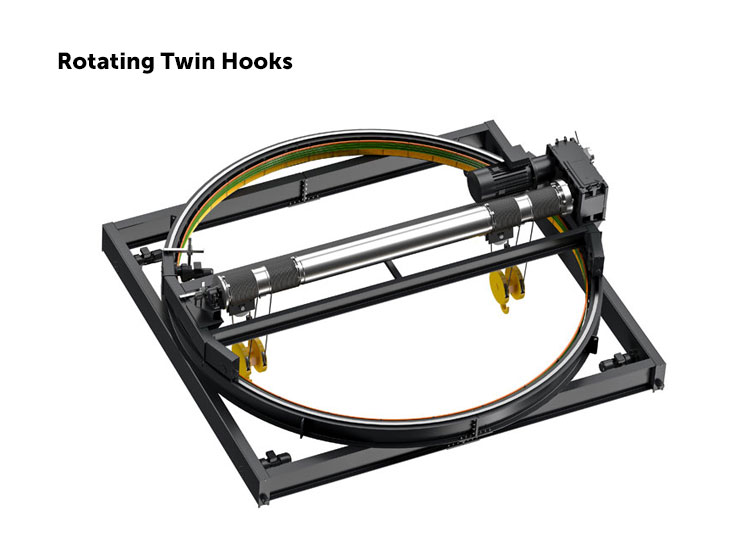

- Twin hoists roped into a single bottom block and hook for super high lifts.

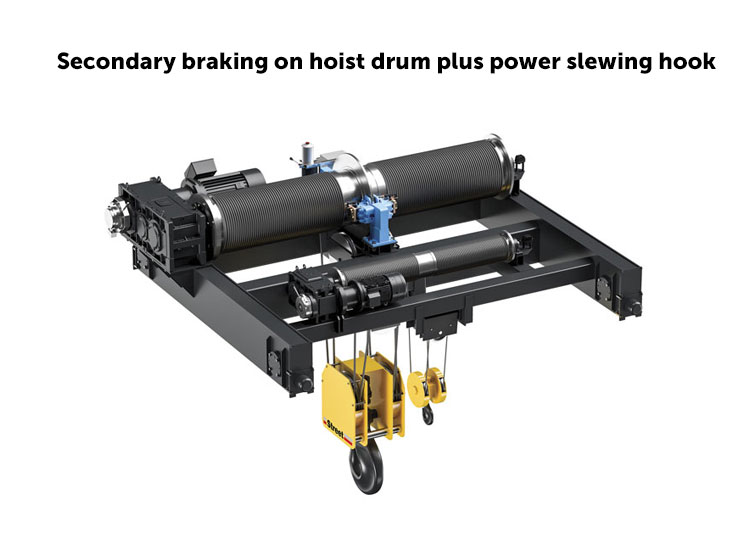

- Power slewing mechanism in the hoist frame or in the hook block.

- Hoists integrated with grabs and lifting devices.

- Second hoist brake mounted on the hoist motor to ensure safety in the event of primary hoist brake failure.

- Second brake acting on the hoist drum which is applied automatically in the event of over-speed, to ensure safety in the event of failure of any component in the hoist transmission prior to the hoist drum.

- Mechanically failsafe load arrestor based on the worm and wheel principle, which also provides independent over-speed and overload protection with optional load recovery capability for nuclear applications.

- Regenerative braking systems on variable frequency drives.

- Bottom block operated over-hoisting limit switch in addition to the standard rotary limit switch.

- Load Dependent Speed (LDS).

- No Load Express Lift.

- Safe torque off on variable frequency hoist.

- Remote Control with optional LCD status display.

- Micro-speed hoisting and lowering.

- Anti-sway control (prevents traverse movement causing hook swing).

- Slack-rope detection and prevention.

- On board or remote condition monitoring including design working period (DWP).

- Design for use in non standard ambient temperatures -20⁰C to +70⁰C.

- Hoist modifications for lifting hazardous loads such as molten metal.